EPC

EXHAUST FANS

The Need of an Exhaust Fan

Whether it's in an office or a factory, a laboratory or an auditorium, a bakery or an kitchen,

the air that we breathe gets stale and heated with time-making the place uncomfortable and unhealthy. The heat gets

unbearable, the steam or smoke highly irritating. What is then desperately needed is an improved air condition or

adequate number of air changes. This is obtained only through powered ventilation - an Exhaust Fan. It squeezes out

polluted air and allows inflow of cool and fresh air - in a double-action way. Features

The EPC Exhaust Fan is provided with capacitor, start and run induction motor of robust construction, totally

enclosed, continuous rated type and specially designed for fan duty. Direction of rotation can be changed simply by

interchanging connections of the stator windings. Conforms to I.S. Specifications No. 2312/1967 and is generally

provided with class 'A' insulation; class 'E' insulation can be offered to meet special requirements. Fan motors

have two ball bearings adequately lubricated

The largest range of I.S.I. marked exhaust fans in India

EPC Exhaust Fan has the widest range to cover and suit your requirement from 230 mm (9") to

900 mm (36") in both single and three phases.

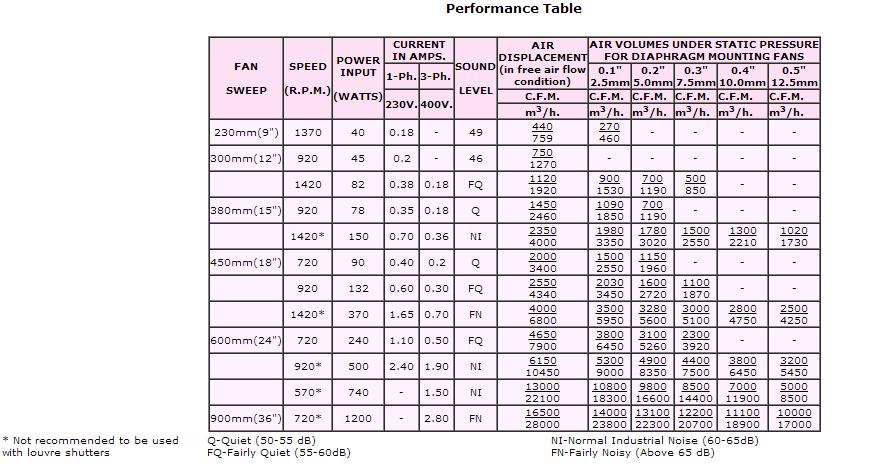

PERFORMANCE TABLE

How To Install

| Exhaust Fan-The Way To Install |

Positioning of Exhaust Fans is an important factor in ventilation.

Wrong positioning will make installation meaningless. Fans should be installed away from the air - paths or

inlets as far as possible, enabling them to draw out polluted air and draw in fresh air quickly. Fans should

be placed high on the wall - opposite to the air - inlets, for being polluted, the warm air starts rising.

Placing them near doors or windows will cause air movement to be short circulated between the fans and

adjacent inlets - keeping part of the room unventilated (see illustration above). It is preferable to use

combination of small and medium sized fans than one large fan.

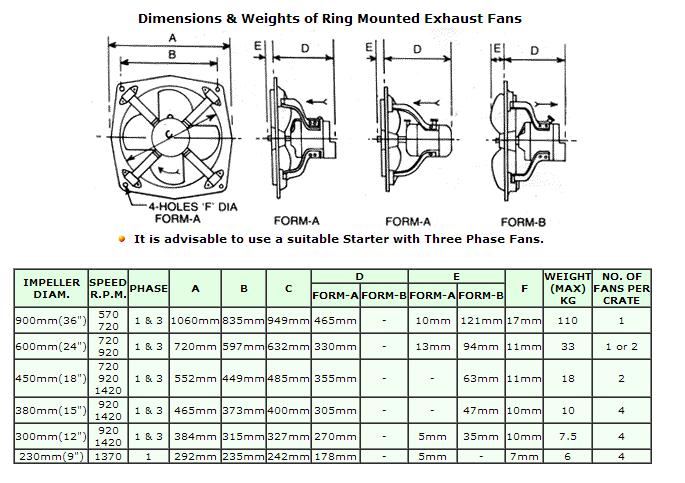

EPC Exhaust Fans can be supplied with special mounting arms (but

without rings) to function against resistance. This helps radial flow from

the wing tips - reducing back flow losses and increasing pressure development. The ring mounted fans give

maximum volume under free air flow conditions while the diaphragm mounted fans give maximum volume under

free air flow conditions while the diaphragm mounted fans work against resistance.

Fans, exposed to weather, are subject to moisture and dust - laden

atmosphere-- necessitating special protective treatment. As required, EPC Exhaust Fans can be coated with

epoxy paint or chlorinated rubber paint for protection against corrosive atmosphere. While working in

moisture - laden atmosphere,the motor winding may absorb water causing damage to motor insulation. The

Fans can provide special impregnation of motor windings, protection against ingress of water and guarantee

protection against ingress of water and guarantee protection of all interior and exterior

surfaces.

Accessories

| Wire Guard:

Protection For Impeller |

The motor and impeller sides of EPC Exhaust Fans may be provided with strong

wire guards. Motor side guard fits over mounting arms while impeller side guard

fits into the orifice in the fan ring or diaphragm.

|

Regulators may be supplied for use with 230 mm , 300 mm, 380 mm, 450 mm, 600

mm, single phase fans. They have four speeds, are metal clad and of auto -

transformer type for 450 mm 1400 r.p.m. and 600 mm 920 r.p.m. fans and of choke

type for others. Electronic Stepless Regulators can also be supplied with all

single phase fans.

|

|

These are made of aluminium, fitted into a steel frame with four fixing lugs.

They are opened by fan draught and closed by gravity when the fans are switched

off.

|

|

They provide an effective protection for fan outlets in exposed position. They

protect the fans from weather and prevent opposing winds to restrict fan

output. Reduction in delivery of free air due to fixing flanges. They are

strong and coated with anti - rust paint.

|

|

EPC Exhaust Fan has the widest range to cover and suit your requirement from

230 mm (9") to 900 mm (36") in both single and three phases.

|

Fans, of all sizes, are packed in cartons - Fan Motor in one, Impeller Fitment

in the other. Instructions regarding installation of electrical connection are

given with each fan.

|

| I.S.I. Certification

Marking |

EPC's is the only

Exhaust Fan in India having its full range certified by the Indian Standard

Institution.

|

|

Air Change

EPC Exhaust Fans Play A vital Role

In...

Ventilation in a factory is a

delicate problem. Serious air pollution from excessive heat, smoke and dust affects the general

health, overall efficiency and output in a factory. EPC Exhaust Fans will solve this

problem.

Many badly planned public auditoriums become hot and stuffy immediately after their doors are

closed and the show begins . Ceiling fans or air circulators cannot ease this situation except

Exhaust Fans.

Most cafeterias lack proper ventilation--cookingodors

and steamy - muggy air float

constantly. It is desirable that EPC Exhaust Fans should be fitted here to enable people to eat

their food at ease.

Although banks in metropolitan cities are better ventilated, it's not so

in towns and villages . The hectic working pattern in banks require hygienic and comfortable

working condition - ensured only by Exhaust Fans.

|

A library room should be airy and

damp - proof as possible both for the health and hygiene of library users and thousands of

books stored therein. EPC Exhaust Fans protect it from moisture, pollution and

contamination.

Our kitchen and toilet are often gloomy and stuffy with insufficient air inlets. They

need minimum 10 to 20 air changes per hour. EPC Mini Exhaust Fans

eliminate malodor and stuffiness.

Besides general ventilation, EPC Exhaust Fans are

widely used in Room Coolers - the most effective and economical device used in dry and low

humid climates to keep houses and working places cool

andcomfortable. The 450 mm (18") single phase 720 r.p.m. and 920

r.p.m. fans are ideal for domestic purpose and 600 mm (24") 720 r.p.m. and 920 r.p.m. for large

Room Coolers in cinema halls, restaurants, etc. Simple enough, one can make such a cooling unit

at home at a very low cost.

|

| Air Change-The Sole

Solution |

Air change is thus the most vital factor for an environment. Varying from location to location,

it depends upon the surrounding, the number of people working and also the nature of work. A

bank or an office requires much less air changes than a foundry or a boiler house. The table

shown is a general guide. To determine the number of Exhaust Fans required, multiply the

cubical content of room (length x width x height) in metre or feet by the number of air changes

required and divide the result by air delivery of fan (see table).

| Location |

Air-Changes

Per Hour |

| Assembly

Halls |

8-12 |

| Bakeries |

10-30 |

| Banks |

6-10 |

| Banquet

Halls |

12-20 |

| Cafes /

Restaurants |

15-20 |

| Canteens |

15-25 |

| Club

Rooms |

8-12 |

| Factories |

10-20 |

| Garages |

8-20 |

| Hospitals |

8-12 |

| Hotel

Bars |

12-20 |

| Kitchen

(domestic) |

10-20 |

| Kitchen

(commercial) |

20-30 |

| Laboratories |

10-15 |

| Lavatories |

15-20 |

| Offices |

8-12 |

| Paint

Shops |

30-50 |

|

|